Microfluidic devices are analogous to circuit boards, and they can be programed to perform all kinds of laboratory tasks on a small scale. They have the potential to perform all kinds of medical tests involving body fluids in a short time and using very small samples.

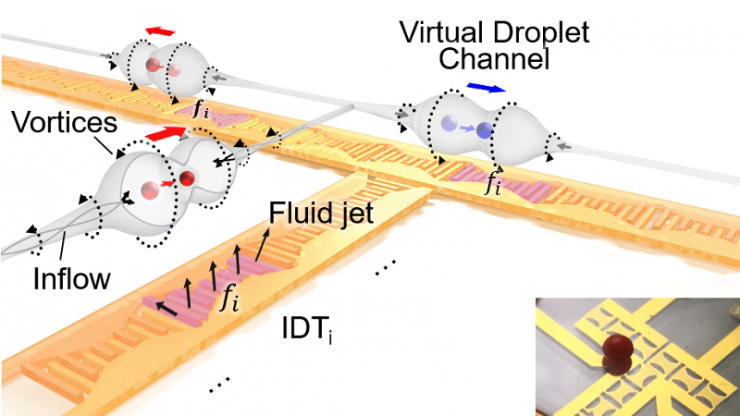

While circuit boards pass electricity, which can be abstracted and quantified as bits, microfluidic devices tend to work with liquids that can mix with one another and contaminate each other. For microfluidic devices to approach the logic abilities of circuit boards, the fluids within have to somehow be perfectly separated from each other until the time that they’re expected to mix. Conventional microfluidic gates and valves aren’t adequate in this context, so researchers at Duke University have now developed a way to keep individual droplets from touching each other while moving them around using sound waves inside a microfluidic device.

Scaling up this approach could lead to programmable and rewritable microfluidics that can be used multiple times and in different ways. “Our new system achieves rewritable routing, sorting and gating of droplets with minimal external control, which are essential functions for the digital logic control of droplets,” said Tony Jun Huang, the corresponding author of the study appearing in Science Advances. “And we achieve it with less energy and a simpler setup that can control more droplets simultaneously than previous systems.”

One of the main tricks of the new approach involves coating the interior of a microfluidic device with a layer of oil. This prevents water-based droplets from leaving behind any of their residue as they are propelled inside the device.

To actually move the droplets within, an array of tiny piezoelectric transducers is positioned near the fluid channels. These generate sound waves that resonate with the oil coating nearby, creating waves within it that push on any nearby droplets. This is not as easy as it sounds since waves from nearby transducers interact with each other and bounce off the walls of the microfluidic device. To create the necessary vibrations that propel droplets toward their destinations, the system had to be finely tuned to generate the necessary vortices within the oil coating. The new control mechanism is so good that droplets can be moved simultaneously and very precisely along two different axes.