Researchers at the National Institute of Standards and Technology (NIST), which is part of the US Department of Commerce, have developed a new technique to 3D print soft objects, such as hydrogels, at a higher resolution than previously possible. The technique uses X-rays or electron beams to crosslink the gels, helping to create complex structures at a nanometer scale. The technique could have the potential in creating engineered tissue constructs for regenerative medicine applications.

Soft materials, such as hydrogels, have significant potential in tissue engineering, given their mechanical properties and biocompatible nature. 3D printing such materials could allow for custom implants but has been hampered by poor resolution that impedes the types of fine structural details that would be useful in tissue-engineered constructs.

Typically, 3D printers function through a simple layer-by-layer deposition. However, in the case of hydrogel printing, light is typically used to activate crosslinkers within the printed liquid, allowing them to create polymer chains within the printed material and form the desired gel structure. So far, this light-based curing process hasn’t resulted in the type of resolution that would be particularly useful for implantable tissue engineered constructs.

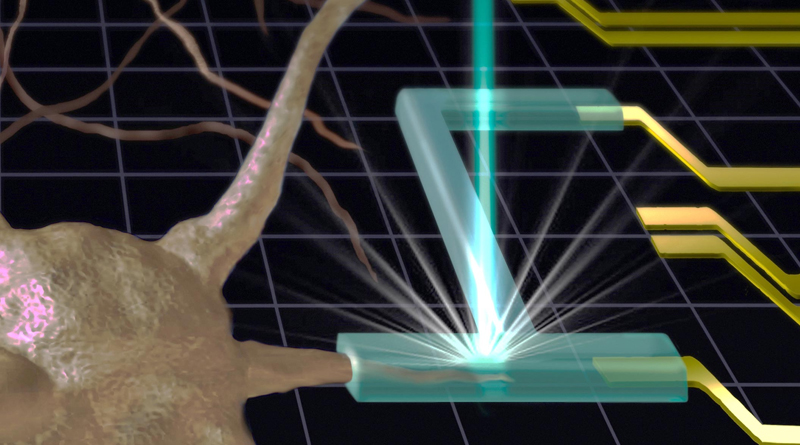

The NIST researchers used either X-rays or electron beams to create printed gel structures. This method has the advantage of relying on tightly focused beams that can create fine structures within the printed objects, and does not require additional crosslinking molecules to be added to the gel.

Prior to this new technique, radiation sources used in this way could only be operated within a vacuum, making it impossible to print gel structures, as the printed liquid would evaporate before forming a gel. The NIST researchers used an ultrathin silicon nitride barrier placed between the vacuum and the liquid to prevent the liquid from evaporating while still allowing the X-rays or electron beams to affect the liquid.

So far, the technique can be used to create structures that are 1,000 times thinner than a human hair. Strikingly, the researchers believe that with optimization, the technique could create structures as small as viral particles.