Global orthopaedic splints and casts market was valued at over $2,1 billion in 2017, and is projected to exhibit a CAGR of 6.1 per cent over the forecast period (2018 – 2026), highlighted a new report by Coherent Market Insights.

Casts and splints are orthopaedic devices used to protect and support broken or injured bones and joints. They help in immobilizing the injured limb to keep the bone in place until it fully heals. Casts differ from splints because they provide more support and protection for a limb that is injured or broken. They are made from materials like plaster or fiberglass that can be easily molded to the shape of the injured arm or leg.

Splints, also known as half-casts, provide less support than casts, but are faster and easier to use. They also can be tightened or loosened easily if the swelling in the arm or leg increases or decreases. A cast might have to be replaced during the healing process if the injured area becomes less swollen and the cast gets looser. In that case, the cast might be replaced with a splint to provide more freedom of movement.

Splints, also known as half-casts, provide less support than casts, but are faster and easier to use. They also can be tightened or loosened easily if the swelling in the arm or leg increases or decreases. A cast might have to be replaced during the healing process if the injured area becomes less swollen and the cast gets looser. In that case, the cast might be replaced with a splint to provide more freedom of movement.

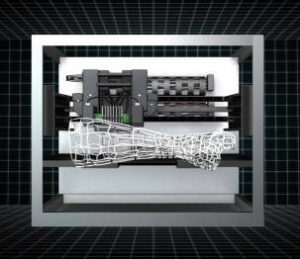

The recent report titled ‘3D Printing Medical Devices Market by Component (3D Printers, 3D Bioprinters, Material (Plastic, Metal, Ceramic), Software & Services), Technology (EBM, LBM, Photopoly-merization, 3DP, and DD), Product Type (Prosthetics, Implant) – Global Forecast to 2022’, highlighted that the global 3D printing medical devices market is expected to reach a value of $1.88 billion by 2022 from $0.84 billion in 2017, at a CAGR of 17.5 per cent from 2017 to 2022. According to the report, key factors such as technological advancements, increasing public-private funding, and growing applications in the healthcare industry are the major factors driving the growth of the 3D printing medical devices market across the globe.

Furthermore, global orthopaedic splints and casts market size, by Product Type (Casts and Splints), by End User (Hospitals, Orthopaedic Clinics, and Ambulatory Surgical Centers), and by Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) was valued at $2,160.6 million in 2017, and is pr ojected to exhibit a CAGR of 6.1 per cent over the forecast period (2018 – 2026), as highlighted in a new report published by Coherent Market Insights.

The orthopaedic splints and casts market is expected to gain significant traction over the forecast period, as manufacturers in the market are focused on developing cost-effective fiberglass casts and splints with innovative design and biocompatible materials.

Increasing incidence of trauma associated with road accidents, falls and sports injuries causing severe skeletal injuries is also expected to propel the or thopaedic splints and casts market growth.

Increasing incidence of trauma associated with road accidents, falls and sports injuries causing severe skeletal injuries is also expected to propel the or thopaedic splints and casts market growth.

According to the Global Burden of Disease report published by Lancet in 2015, road injuries is one of leading causes amongst 20 causes of the disease burden worldwide.

Also, according to the World Health Organization (WHO) Fact Sheet 2018, road accidents cause between 20 million and 50 million injuries every year worldwide and are the leading cause of death among people aged 15-29 years. Also, over 1.25 million people die each year as a result of road traffic crashes.

Furthermore, falls from height cause serious injuries, leading to hip or knee fractures, bruises, and head trauma. Again, according to the WHO, in 2018 around 37.3 million falls requiring medical attention were recorded, where an estimated 646,000 individuals die from falls globally every year.

In an interview with MediWorldME, Diana Hall, president/founder of ActivArmor explained how their custom-made 3D casts and splints empower patients with the freedom to maintain their active lifestyles.

What is ActivArmor?

ActivArmor’s revolutionary digital casting/splinting process takes the time consuming, custom-fitting work out of the clinic, improving patient throughput and billing opportunities throughout the healing phases.

“ActivArmor is the first commercially available 3D cast/splint in the US consumer marketplace . ActivArmor replaces the traditional casting and splinting process with inventory and staff time, with a quick, digital in-clinic service. ActivArmor devices are custom fit to the millimeter of each patient’s unique body map , water proof, breathable , and hygienic. The patient can wash and shower like normal with these breathable, comfortable plastic casts on. They are being prescribed for acute injuries like breaks and sprains (like a cast), and for chronic conditions like carpal tunnel (like a splint),” notes Hall.

A traditional cast wraps all the way around an injury and can only be removed in the doctor’s office. All casts are custom-made with fiberglass or plaster. However, a splint is like a ‘half cast.’ The hard part of a splint does not wrap all the way around the injured area. It is held in place by an elastic bandage or other material. Unlike casts, splints can be easily removed or adjusted. Many splints are custom-made from fiberglass or plaster. Others are pre-made (‘off-the-shelf’) and come in lots of shapes and sizes for different injuries.

A traditional cast wraps all the way around an injury and can only be removed in the doctor’s office. All casts are custom-made with fiberglass or plaster. However, a splint is like a ‘half cast.’ The hard part of a splint does not wrap all the way around the injured area. It is held in place by an elastic bandage or other material. Unlike casts, splints can be easily removed or adjusted. Many splints are custom-made from fiberglass or plaster. Others are pre-made (‘off-the-shelf’) and come in lots of shapes and sizes for different injuries.

“ActivArmor devices are all custom designed, so they are adaptable for use with advanced healing options like bone stimulators (ultrasound), muscle stimulators (to reduce muscle atrophy), TENS units (for pain management), biomonitors, etc. In addition, doctors have the option to protect post-surgical hardware, and expose incisions for observation and treatment. ActivArmor does not trap bacteria against the skin like traditional options, and allows for cleaning, which could reduce infection and skin irritation”.

“ActivArmor works like a traditional cast for bone fractures. It is up to your doctor how long you must wear it, but we have had reports of reduced healing times when used in combination with other technologies such as bone stimulators,” continued Hall.

“ActivArmor immobilizes the patient’s affected area just like a traditional cast or splint, but allows them to continue to perform their daily activities like gardening, doing the dishes, exercising, washing, all of their regular lifestyle activities during the healing phase. When used in combination with advanced healing options like ultrasound and muscle stimulators, healing and recovery time can be reduced.” – Diana Hall, president/founder of Activarmor

Maintaining active lifestyle

With traditional casts, you must be careful not to get them dirty and wet. With ActivArmor, you can sweat, swim and wash with them like normal. If you work or play in a dirty environment, you can continue to do that in ActivArmor. If you are planning a beach vacation, you

would not be held back from participating in the summer activities. If you work in medical or food handling careers, you can also continue to make a living while being immobilized, according to the company’s president.

ActivArmor empowers patients with the freedom to maintain their active lifestyles. ActivArmor can save physicians time and increase clinic efficiencies by reducing skin irritation complaints including moisture, material waste, remov al process , recasting and adjustments.

“ActivArmor immobilizes the patient’s affected area just like a traditional cast or splint, but allows them to continue to perform their daily activities like gardening, doing the dishes, exercising, washing, all of their regular lifestyle activities during the healing phase. When used in combination with advanced healing options like ultrasound and muscle stimulators, healing and recovery time can be reduced. Some patients have reported requiring no or reduced pain medication when used in combination with TENS units and topicals. ActivArmor transitions with the patient by having a non-removable closure (like a cast), being adjustable for swelling as needed, and being able to transition to a removable closure (like a splint).

“As long as their doctor approves it for their injury or condition, patients can continue to sweat, work, get dirty, do dishes, bathe, swim, and train as normal, because ActivArmor does not hold them back in the ways that traditional casts and splints do by being stuffy, unhygienic, itchy and smelly.”

Patient benefits

ActivArmor is an obvious benefit to patients due to its hygienic, breathable, waterproof qualities, but it also saves them time and money for the patient as it can be used throughout the healing phases instead of having scary saws cutting casts off and reapplying for every future exam or x-ray.

“It also transitions into a splint for support and protection in later healing phases of an acute injury. The clinic does not need to stock or use inventory, and use staff time and clinic space for casting or forming splints, for adjustments, cutting casts and re-applying them throughout the patient’s healing phases. Doctors now have unlimited design options – coverage areas, thickness or thinness, adaption for use with advanced healing technologies and topicals, and expose any area for the ability to observe wounds, incisions, swelling and the skin condition during immobilization. Any doctor has that ability now by simply writing a prescription for ActivArmor”.

“With traditional casts, your skin cannot breathe, and you cannot wash as normal, so your skin gets ir ritated, trapping sweat, moisture and bacteria against the skin. If you have an incision or laceration, you cannot observe and treat it, so infections can go undetected. The inability to bathe can make it itchy – patients can injure themselves sticking things down their casts to scratch. They can get smelly over time, which is embarrassing, and some patients have cast-claustrophobia, which causes anxiety and stress. Casts require loud saws to be used to remove at each exam/x-ray, which can be very scary for kids. ActivArmor is hygienic, breathable, reusable and completely painless,” added Hall.

“ActivArmor devices are 100 per cent biocompatible plastic. They are designed to allow for airflow and breathability while immobilizing completely. You can wash like you do normally. Athletes can sweat in them and ice-bath on the sidelines. Some patients, who feel trapped or claustrophobic by traditional casts, including those with PTSD, can wear ActivArmor because they can see and touch their skin. Elderly patients with thinning skin issues or mobility problems can easily get in and out of the shower/tub with them. Diabetic patients can see and treat skin ulcers or accommodate swelling.”

The patient simply makes an appointment with any of the providing clinics listed on the website, and bring a prescription for a custom splint from their doctor. During the appointment, the technician will perform an eye-safe, painless, 30-second body image scan of the patient’s limb, and upload the model to ActivArmor with specific design instructions based on the doctor’s orders and the patient’s lifestyle. The patient will be put in a temporary solution (splint or bi-valved cast), and the ActivArmor device will be shipped back to the clinic within 3-4 business days for the patient to pick up.

“Traditional splints can rub or deform and require adjustments. They must be heated and formed directly onto the patient, which can be painful. They are not breathable, and the Velcro can get dirty and wear out over time. Patients are often non-compliant with traditional options because they are cumbersome, uncomfortable and ugly, which can result in longer healing times and increased pain. Doctors have very limited options on customization for each patient’s unique needs as far as thickness, coverage area, closure mechanisms and exposure areas. Patients often need multiple casts and then a splint through their entire healing phase, requiring additional time and cost at each phase.”

“Our trained CAD technicians hand-design every single device according to the doctor’s prescription and the patient’s scan. That design is then 3D printed and hand-finished at an FDA-registered medical device-manufacturing site”.

Bold business move

Diana Hall is a chemical engineer by trade and after working for many years in Fortune 500 companies, she took some time off and ran a mentoring program for children in poverty in her hometown. Some of the children had domestic violence and substandard living conditions.

“I knew that the technology was available to provide a better alternative, so I looked into why it was not available to consumers. I addressed the design and regulatory issues and developed a business model to provide a digital custom casting/splinting service to doctors and hospitals. It’s now available at select clinics across the country, and we are growing every day.”

When asked if 3D printing technology will revolutionize the medical technology industry, Hall shared her opinion: “I think that customization is the future of medicine – inventory of standardized products in all different sizes and designs is costly and does not allow for today’s patients’ active lifestyles. Doctors are looking for ways to increase throughput and provide customized/ precision medicine for their patients, and 3D printing of devices and medications will allow that to become more available and affordable.”